Services

Engineering

Veel van onze projecten vergen veel denkwerk en engineering. Wij ontwikkelen producten en projecten voor klanten in diverse sectoren. Onze engineers hebben ruime ervaring in het engineren van projecten. Wij staan naast u om dit project tot een succes te maken.

Engineering

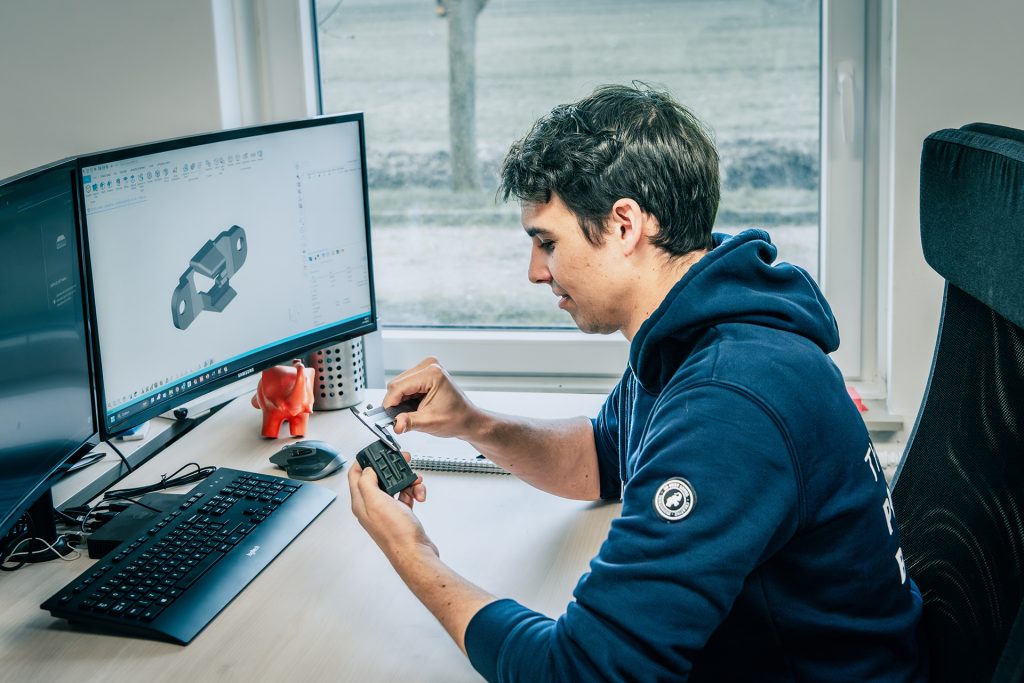

At 3D Next Level, we have a team of experienced engineers who work closely with our clients. Our engineering process goes far beyond just uploading a 3D model and 3D printing. We understand every component that we print and actively collaborate with the client to find the best solutions.

Our clients can trust that we deliver a complete end product. In addition to 3D printing, we add supplementary brackets, bolts, nuts, or even metal adhesives as needed to meet their specific requirements. We also offer various additional in-house production methods, such as rotocasting, rim-molding, and finishing, to meet different demands.

At 3D Next Level, we don't stop at printing a prototype; we extensively test our products in practice. We conduct tests on our self-developed test benches and persist until we achieve the most optimal product for the customer.

We believe in providing a complete service and demonstrating responsibility throughout the entire process. From the initial contact to the delivery of the end product, we offer a comprehensive journey from A to Z. Our clients can rely on us for expert guidance, innovative solutions, and high-quality products.

"We assist you from A to Z and deliver a finished product."

TESTIMONIALS

What customers say about 3D Next Level

Curious about what we can do for you? Don't wait any longer and get in touch with us.

BRUTE PROCESS STEP BY STEP

TESTIMONIALS

The engineering process step by step