Production techniques

3D printing

3D printing has become increasingly popular in recent years as a supplementary production technique. At 3D Next Level, we believe that 3D printers have the potential to replace traditional production methods more frequently. This is due to several reasons, including:

- The availability of increasingly better materials on the market and a wider range of options.

- The speed of 3D printing for production has increased significantly.

- There's an increasing capability to 3D print larger dimensions.

- No setup or mold costs, and no Minimum Order Quantity.

- Local production without massive waste streams is sustainable and ethically responsible.

- With 3D printing, it's entirely possible to make design adjustments as needed during the process.

- The costs for 3D printing are becoming increasingly favorable.

What is 3D printing?

3D printing, also known as Additive Manufacturing (AM), Rapid Prototyping, or Rapid Manufacturing, is a production technique where a digital (3D) file is converted into a tangible (3D) object. The object is built layer by layer by a 3D printer.

Waarom 3D Next Level?

- De voorloper in Nederland op het gebied van massaproductie 3D-printen

- Many high-quality materials available

- High-quality 3D printers in-house to provide the desired service

- Intensief partnerschap & testpartner bij onze leveranciers voor nieuwe materialen

- Years of experience in the 3D printing industry

Our 3D printers

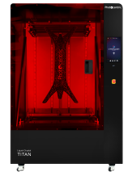

Photocentric Titan (SLA)

695 x 385 x 1200mm

86mm per hour

Photocentric magna (SLA)

510mm x 280mm x 350mm

16mm per hour

Photocentric opus

(SLA)

310 x 174 x 220mm

18mm per hour

Massivit

142 x 111 x 180cm

35cm per hour

Sinterit lisa pro (SLS)

150mm x 200mm x 260mm

3mm per hour

Hierboven ziet u een selectie van onze 3D-printers. Van de meeste 3D-printers hebben wij er meerdere 3D-printers staan. Daarnaast hebben wij ook nog aanvullende 3D-printers die wij hoofdzakelijk inzetten voor Creative.

technische informatie

3D printing

What 3D printing techniques exist in general?

There are several techniques to create a (3D) object, mainly by building the object layer by layer. Below are brief descriptions of the three most well-known 3D printing techniques:

The most well-known technique is FDM printing, this method involves melting a plastic filament and depositing it layer by layer.

With SLS printing , objects are formed by fusing (sintering) ultra-fine powder particles (also layer by layer) using heat, such as from a laser

SLA printing, also known as stereolithography , is a term used to describe various methods that fall under this category. With this technique, each layer is exposed from a liquid bath containing a UV-sensitive liquid polymer (resin). The liquid solidifies exactly where the UV light shines. The light sources can be a UV laser, UV LEDs combined with an LCD screen, or a projector (DLP), but developments are advancing rapidly.

Over the years, 3D Next Level has gained extensive experience with all three of these techniques and their many variations. Currently, we primarily focus on SLA and SLS printing technologies.

SLA 3D printer

- High level of detailing

- Isotropic material (material properties are the same in all directions)

- Both large and small 3D prints are possible with SLA 3D printing

- Fast printing method, large quantities feasible per day

- Surface quality is high, comparable to injection-molded products

- Complex models possible

- SLA can 3D print hollow objects

- Various high-quality materials (resins) available

- Non-porous

Challenges of SLA 3D printing:

- 3D prints are supported with supports that need post-processing

- The 3D printing process must be executed well to prevent warping

- Materials are becoming stronger, tougher, and more durable. However, there are limitations in some cases. Therefore, it's essential to carefully consider what is feasible for each application

- We glue threaded inserts into our 3D prints; they cannot be melted in

SLS 3D printer

- Complete design freedom during 3D printing because it is printed without supports

- No/less post-processing of the 3D prints because there are no supports attached

- Through "digital nesting," many parts can be printed simultaneously in one batch

- Proven status and materials are all-round and well-known (PA12 and TPU)

- Materials are strong and tough (post-processing is easy with this material)

- High temperature resistance (HDT)

Challenges of SLS 3D printing:

- Large-format 3D printing with this technique is not yet possible

- The surface is porous, which can be a challenge for some applications

- Detailing level is lower/coarser compared to SLA 3D prints

- Some geometries are challenging to print due to heat and warping