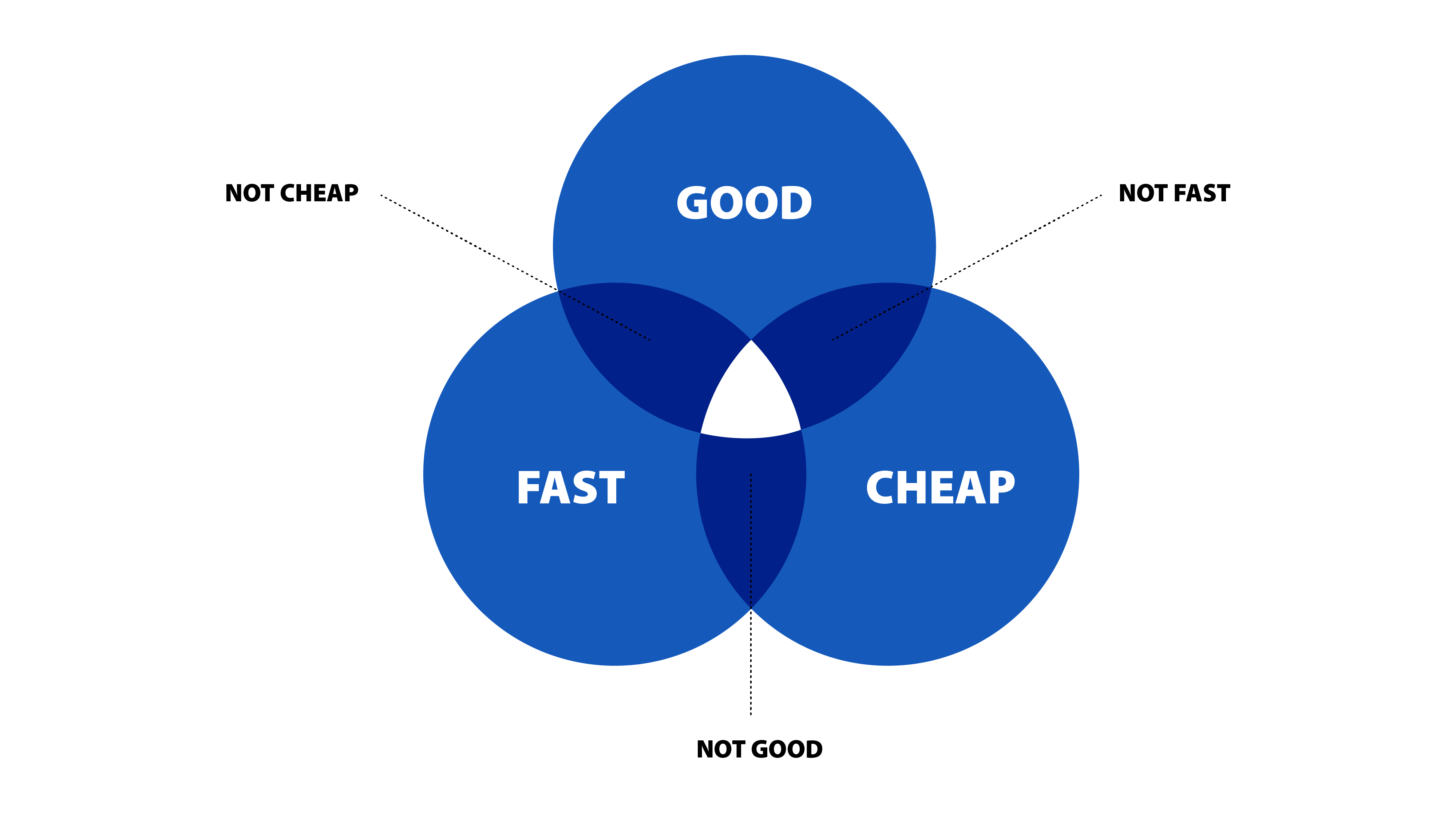

There's an old saying that goes something like: "Fast, good, or cheap - pick any two." Known as the Iron Triangle. The general concept is that when making a product, you have three choices: make it fast, make it cheap, or make it good. Developing something quickly of high quality? It's possible, but it will be very costly to do so. You can develop something quickly and cheaply, but it won't be of high quality. Or you can develop something of high quality and low cost, but it will take time.

Every day, we are challenged by the demand for more complex products, with shorter lead times, and at lower prices. It's an almost impossible demand according to the iron triangle. However, with the help of innovative technologies like Additive Manufacturing (AM), we can achieve what was previously impossible with traditional production technologies.

Think Smart. Print Smart.

What are the actual benefits of Additive Manufacturing? Why is this method actually smart? And why do customers choose this option? We'll take you through the gains to be made with AM.

Fast lead times

Because no molds or intricate programming are needed for production, with 3D printing, it's possible to realize a product within a matter of hours.

Unlimited design freedom

Printing can be done in virtually any shape. With conventional production technologies, designers are forced to adapt their concepts to the constraints imposed by the manufacturing process, often resulting in inefficient or overdimensioned parts.

Local production

Due to recent circumstances, local production becomes much more interesting than outsourcing abroad. Additionally, there's no need to move products internationally. This saves on transportation costs and makes a positive contribution to the environment.

Sustainable production

AM can be considered sustainable because there is virtually no material waste, and in some techniques, there's no waste stream at all.

No need for large storage

Thanks to the fast production method, there's no longer a need to maintain large inventories. The benefits? Cost savings on warehouse space and flexibility when it comes to revising existing models.

Customization.

Because digital files are used, it's very easy to make changes. It doesn't matter whether it's a uniform series or a series with specific model-level adjustments (names, numbers, technical modifications, colors, etc.).

Lightweight

The design freedom of AM offers opportunities to make your products stronger and lighter with fewer potential weak points.

Reduced assembly costs

You can print components as a single piece. Assembly costs are thereby greatly reduced, and post-processing is only necessary for critical surfaces.

Single pieces and mass production

1 or 10,000 pieces. It's all the same to us. Fast, precise, and high-quality with industrial 3D printing!

Cost-saving

In some cases, a customer may ultimately opt for a conventional technique like injection molding. This can also be a very logical decision. However, even then, 3D printing is very interesting in the prototyping process. Revisions can be made early on, and fits can be checked, reducing potential failure costs.

If AM is used correctly, it has many advantages over conventional production technologies. In theory, 3D printing can represent a win-win scenario. However, in practice, we see that the traditional mindset is very stubborn and prevents the full potential of AM from being realized.

To assist designers in making the transition to geometric freedom, complexity, and change, we offer workshops and brainstorming sessions to update your team's AM knowledge and gain valuable insights.

It's nice to hear what the possibilities are. 3D printing isn't the first technique I think of for producing technical parts. That's different now.