Technische informatie

3D printing

3D printing has become increasingly popular in recent years as a supplementary production technique. At 3D Next Level, we believe that 3D printers have the potential to replace traditional production methods more frequently. This is due to several reasons, including:

Wat is 3D-printen?

3D printing, also known as Additive Manufacturing (AM), Rapid Prototyping, or Rapid Manufacturing, is a production technique where a digital (3D) file is converted into a tangible (3D) object. The object is built layer by layer by a 3D printer.

What 3D printing techniques exist in general?

There are several techniques to create a (3D) object, mainly by building the object layer by layer. Below are brief descriptions of the three most well-known 3D printing techniques:

The most well-known technique is FDM printing, this method involves melting a plastic filament and depositing it layer by layer.

With SLS printing , objects are formed by fusing (sintering) ultra-fine powder particles (also layer by layer) using heat, such as from a laser

SLA printing, also known as stereolithography , is a term used to describe various methods that fall under this category. With this technique, each layer is exposed from a liquid bath containing a UV-sensitive liquid polymer (resin). The liquid solidifies exactly where the UV light shines. The light sources can be a UV laser, UV LEDs combined with an LCD screen, or a projector (DLP), but developments are advancing rapidly.

3D Next Level heeft veel ervaring de afgelopen jaren opgedaan met al deze 3 technieken en de vele varianten daarin. Op dit moment richten wij ons met name op de SLA 3D-printtechniek.

"We use SLA 3D printers because we see the most potential in this method: it's fast, precise, offers a variety of materials, and can handle all sizes. This is what the technical industry needs.

Lennart van den Doel

Technisch directeur 3D Next Level

Our 3D printers

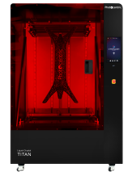

Photocentric Titan (SLA)

695 x 385 x 1200mm

86mm per hour

Photocentric magna (SLA)

510mm x 280mm x 350mm

16mm per hour

Photocentric opus

(SLA)

310 x 174 x 220mm

18mm per hour

Massivit

142 x 111 x 180cm

35cm per hour

Sinterit lisa pro (SLS)

150mm x 200mm x 260mm

3mm per hour

Hierboven ziet u een selectie van onze 3D-printers. Van de meeste 3D-printers hebben wij er meerdere 3D-printers staan. Daarnaast hebben wij ook nog aanvullende 3D-printers die wij hoofdzakelijk inzetten voor Creative.

Waarom 3D Next Level?

- De voorloper in Nederland op het gebied van massaproductie 3D-printen

- High-quality 3D printers in-house to provide the desired service

- Many high-quality materials available

- Intensief partnerschap & testpartner bij onze leveranciers voor nieuwe materialen

- Years of experience in the 3D printing industry

- We blijven investeren & innoveren in 3D-printen met een groeiend R&D Team

De 7 grootste voordelen van (SLA) 3D-printen:

- Steeds betere materialen op de markt en een breder aanbod

- Time van 3D-printen voor productie is enorm gestegen

- Qua afmetingen kan er steeds groter 3D-geprint worden

- Geen opstart- en malkosten en geen Minimum Order Quantity

- Lokaal produceren zonder enorme afvalstromen is duurzaam en ethisch verantwoord

- Met 3D-printing is het prima mogelijk het design gaandeweg nog aan te passen

- Kosten voor 3D-printen steeds interessanter worden

Onze Materialen

- Brandvertragend materiaal

- Uitbrandbaar materiaal

- Flexibel materiaal

- Extra sterk materiaal

- Chemisch resistent materiaal

- High Temp materiaal

- Plant based materiaal

3D-print methodes

De verschillen

Wij geloven bij 3D Next Level het meeste in de SLA 3D-print methodiek. Dit komt met name omdat we in de afgelopen jaren de meeste voordelen hebben ervaren bij SLA 3D-printen en omdat de voordelen van FDM & SLS 3D-printen naar onze mening niet opwegen tegen de nadelen. De voordelen van SLA 3D-printen zal maken dat 3D-printen gedeeltelijk o.a. spuitgieten kan gaan vervangen komende jaren.

SLA 3D-printen

Pluspunten van SLA 3D-printen:

- Hoge mate van detaillering, zonder lijntjes

- Both large and small 3D prints are possible with SLA 3D printing

- Fast printing method, large quantities feasible per day

- Oppervlak kwaliteit is zeer hoog, vergelijkbaar met spuitgiet producten

- Complex models possible

- SLA can 3D print hollow objects

- Various high-quality materials (resins) available

- Non-porous

Challenges of SLA 3D printing:

- SLA 3D-printen is over het algemeen duurder dan FDM 3D-printen

- 3D-prints worden met supports ondersteund, deze moeten soms na bewerkt worden

- The 3D printing process must be executed well to prevent warping

- Er moet per toepassing goed bekeken wat wel en niet kan

Nadelen FDM 3D-printen:

- Weinig detail, veel lijntjes zichtbaar

- Zwakker materiaal t.o.v. SLA 3D-prints

- Detailing level is lower/coarser compared to SLA 3D prints

- Geen snelle printmethode

- Complexe modellen niet mogelijk

Nadelen SLS 3D-printen:

- Large-format 3D printing with this technique is not yet possible

- Oppervlakte is erg poreus

- Detailing level is lower/coarser compared to SLA 3D prints

- Some geometries are challenging to print due to heat and warping

Are you wondering if your product is suitable for this production technique?

Get in touch with us!