What do we do (for you)

Services

We're eager to share our knowledge and experience with you, standing beside you as a production partner to observe and support your unique process. With deep expertise in plastics and other materials, we ask the right questions to precisely understand your product and production process requirements. Our service extends beyond simply 3D printing your product; we collaborate with your entire engineering and R&D team, empowering them to integrate 3D printing (AM) into their workflow. This results in a more efficient, faster, and better overall process.

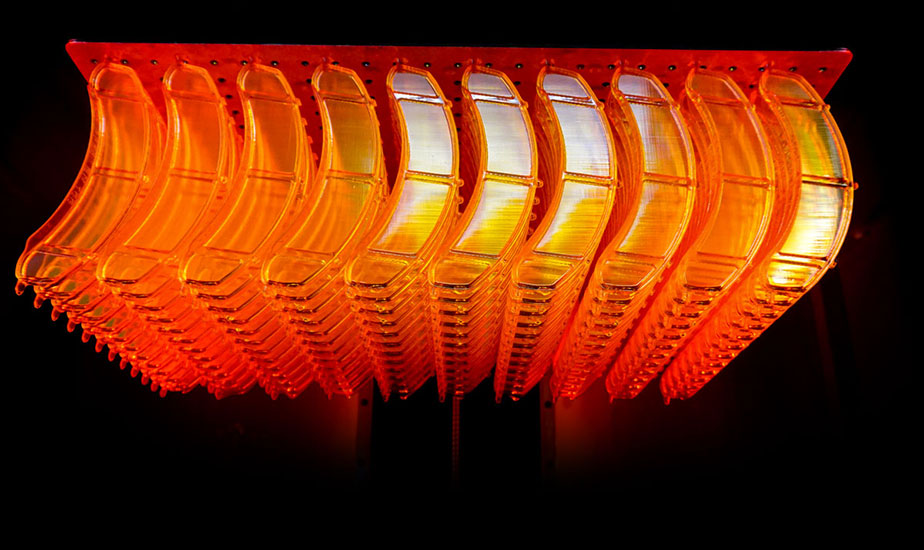

3D printing; batch and mass production

1 to 25,000 pieces. We make it possible! Fast, robust, and detailed through industrial 3D printing! We help you unlock the potential of additive manufacturing (AM)

An additional advantage of 3D printing is that it re-evaluates the production process. We look beyond just printing a product; we consider the entire process.

- Design freedom

- Urgent requests are possible

- Optimizing your product

- Digitally adding text or logos

- Manufacture complex geometric shapes

Additional production techniques

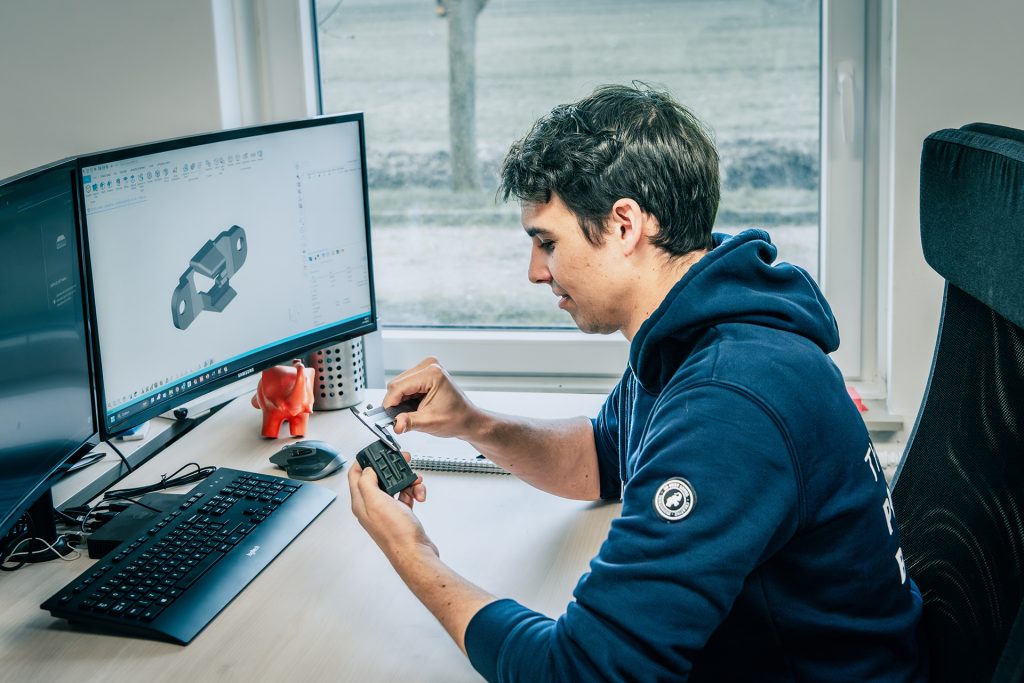

Engineering

At 3D Next Level, we have extensive experience in technical engineering for 3D printing. We are eager to collaborate with you to explore how your product can be better or more intelligently designed for 3D printing (Design For Additive Manufacturing). Through an interactive process, we'll optimize the design by leveraging the customer's specific product expertise along with our material and production knowledge.

- Team of experienced technical engineers

- Access to the right 3D software packages, 3D scanners, and test benches

- Knowledge and experience with production techniques and material expertise

- Over 6 years of experience in 3D printing and production

3D design

Some clients already have a well-developed 3D design of their (technical) product. However, there are often adjustments needed to optimize it for 3D printing. Nevertheless, there's also a frequent need to entrust the entire design process to one of our engineers. We have extensive experience in product design across a wide range of market segments and are eager to collaborate with you on this.

- Team van ervaren 3D-tekenaars & engineers

- We convert your ideas and sketches into 3D printable files.

- We have access to the right 3D software (CAD).

3D scanning

The technique of 3D scanning can be helpful in various ways for product design. Sometimes, the environment where it needs to fit is scanned (for example, a bracket on the hood of a car). Other times, an object may be damaged and needs to be replicated using reverse engineering, allowing the old damaged part to be reprinted.

Absolutely, even in cases where there's a physical object but no existing 3D model, 3D scanning can provide a solution. Feel free to inquire about the possibilities in this regard.

- A highly detailed 3D model derived from the 3D scan.

- Optimizing and customizing your 3D model.

- Reverse engineering from a 3D scan to a usable CAD model.

- Small and large objects possible.

- On-site services available.

Prototyping

3D printing is the ideal methodology for creating prototypes of your product. This can range from a (scaled-down) non-functional component to a fully operational and robust functional part. Often, a series of prototypes is created as rapid iterations are needed to implement improvements and changes quickly. We can swiftly adapt and work with you through this process.

- Customization.

- We can also perform (functional) testing on your prototypes.

- Fully functional with accompanying components (steel, bolts, nuts, bearings).

- Afwerking & Spuiterij

Spuitwerk & Afwerkingen

For finishing our 3D prints, we have an in-house spray painting facility. This means we can paint and finish your product in one or more colors, allowing us to maintain speed in your project.

- Fully smooth finished and painted.

- Sprayed in the correct color(s).

- Also offering options for special paint and VeroMetal coatings.

Assembly and additional components

We prioritize assisting you throughout your entire production process. We often see clients using 3D printing as a replacement for other production methods. This means that our products are frequently used as end products themselves. Because these end products are often directly incorporated, for example, into a machine, we sometimes integrate steel components into the 3D prints. For instance, we may bond threaded bushings or studs into our 3D prints, attach the 3D-printed parts to existing elements, or provide the appropriate fasteners directly. Internal reinforcement with steel or integration with electrical components or LEDs are all services we have experience with. We're eager to collaborate practically to ensure that the part fits seamlessly into the overall machinery or assembly.

- Total solution for your project

- Custom-made molds

- Additional components for fastening and assembly.

Brainstorm & Training Sessie

We passionately advocate for 3D printing as a groundbreaking solution for many of the current processes within a company. To reinforce this message, we offer Next Level Sessions where we engage interactively with engineering teams and provide training. We also tailor our approach to each customer, assessing what works best for them and what doesn't, while thoroughly examining the technical aspects of their company. This way, we form an intensive partnership and assist your team in adopting a new mindset.

If you're interested in learning more about 3D printing for the (technical) industry, book your Next Level Session now. During this session, we'll collaborate with you and your team to explore how 3D printing can add value to your production process and company.

- 3D Printing Expert On-Site

- Workshops for both beginners and experts in the 3D printing market

3D Next Level – Creative specializes in custom-made blow-ups, advertising characters, artworks, scale models, trophies & figurines, and corporate gifts. We are your partner for 3D objects in both large and small formats. Whether it's delivering creative 3D-printed objects or providing comprehensive solutions that encompass everything from 3D design, 3D scanning, painting, decals, LED lighting, steel constructions, transportation, and assembly.

- Blow-ups

- Artworks and sculptures

- Advertising objects

- Trofeeën & awards

- Relatiegeschenken & logo's

- Pretparken & musea

Why choose 3D Next Level?

From A to Z

3D Next Level stands out by offering complete projects. We work closely with our clients from the moment they make an inquiry until the delivery and optimization of the product. We accompany you throughout the entire process. We excel in project management and can involve your team in the entire process as well.

3D-entrepeneurs

Within 3D Next Level, testing and innovation are highly valued. This means that we have an in-house R&D team, and our engineers are always working on bringing development to the 3D printing market. Additionally, we use complementary production methods such as RIM molding, rotocasting, and other conventional production techniques. We are very innovative and think entirely in 3D. For example, we internally 3D print our molds for our products and use this in combination with craftsmanship.

Excellent & reliable

Excellence is one of the key pillars of our company. Delivering quality and offering thoughtful solutions ensures that our clients return and refer new ones. We uphold our promises and maintain honesty and reliability throughout the process. Additionally, our innovative approach sets us apart, as we sometimes explore beyond just 3D printing. We offer supplementary services such as assembly, finishing, mold making, and other production methods.

Thinking along in the entire production process.

We go much further than just 3D printing your product. We enhance your entire production process and are only satisfied when you are happy with the end product. In this way, 3D Next Level becomes your strategic production partner. We conduct tests on-site and on our test benches, analyzing your production process together with your technical team: what can be improved, made more efficient, or accelerated? Additionally, we optimize your product for 3D printing to save time, costs, and unnecessary complexity.