3D printing

Applications

3D printing can be used for various applications in the engineering industry. We utilize 3D printing for:

3D printing production

1 to 25,000 pieces. We make it possible! Fast, robust, and detailed through industrial 3D printing! We help you unlock the potential of additive manufacturing (AM)

An additional advantage of 3D printing is that it re-evaluates the production process. We look beyond just printing a product; we consider the entire process.

- 1 to 25,000 parts per day

- 3D printing as a functional end product

- No expensive mold or die costs

- Production time in days instead of months

- Small and large parts

- Fully functional with accompanying components (steel, bolts, nuts, bearings).

Prototyping

If you're in need of a prototype for your product and considering outsourcing part or all of it, look no further. At 3D Next Level, we've got you covered.

This can be a (scaled-down) non-functional part or a working and robust functional part. Often, a series of prototypes is made because people want to make improvements and changes quickly.

We can even assist you in developing your product, conducting tests, and taking care of the engineering process for you. If you prefer to handle this yourself, we're happy to guide you through delivering a beautiful, high-quality prototype.

- Any dimension is possible

- Finishing with paint

- Engineering & productontwikkeling

- Fully functional with accompanying components (steel, bolts, nuts, bearings).

- Aanvullende services, zoals afwerking & spuitwerk

Scale models

At 3D Next Level, we have extensive experience in creating scale models for events, client relations, gifts, and showroom decoration. We convert your large technical files and assist you from A to Z.

- We convert your large, technical files to create a beautiful scale model

- No limitation in dimensions

- Custom-made display cases, bases, pedestals, and signs

- Full-fledged paintwork in a professional spray booth

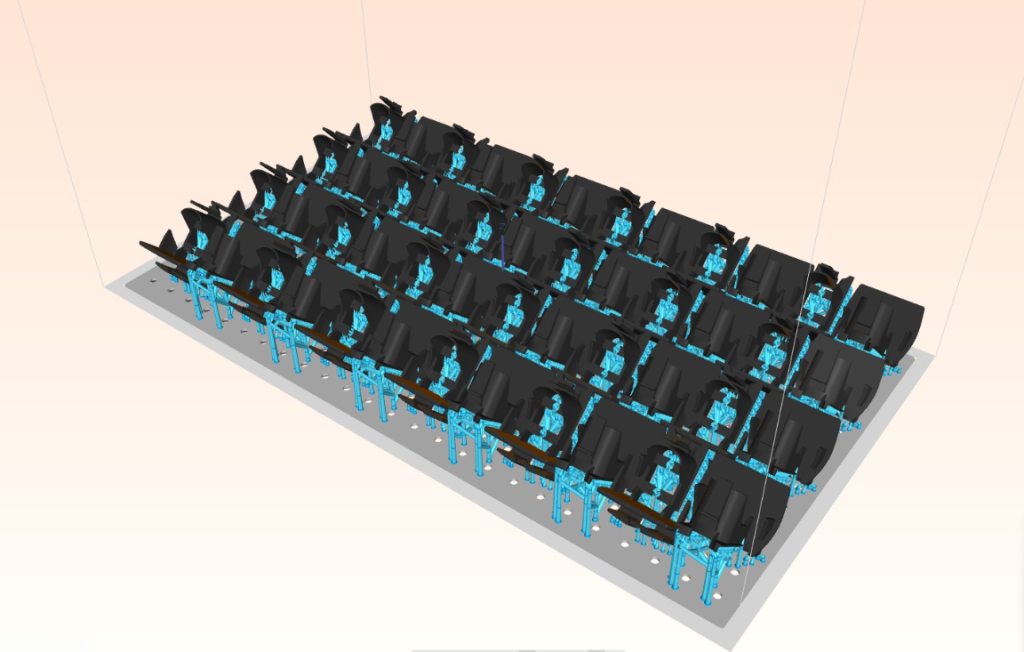

Show models

More and more, we see that technical companies aim to make an impact at trade shows or events. However, they can't always bring their large, heavy machinery and products. To still impress at an event, we can create your machines or products using 3D printing. This way, you can present a tangible model to your potential clients. We can handle the entire project for you: adjusting 3D models, 3D printing in the desired size, reinforcement & assembly, and finally finishing in the desired colors and transportation.

- Lightweight exhibition models

- Any dimension is possible

- We have access to the right 3D software (CAD) to convert your models into printable 3D models.

- Options for integrating screens or displays

- We assist you from A to Z

Why choose 3D Next Level?

From A to Z

3D Next Level stands out by offering complete projects. We work closely with our clients from the moment they make an inquiry until the delivery and optimization of the product. We accompany you throughout the entire process. We excel in project management and can involve your team in the entire process as well.

3D-entrepeneurs

Within 3D Next Level, testing and innovation are highly valued. This means that we have an in-house R&D team, and our engineers are always working on bringing development to the 3D printing market. Additionally, we use complementary production methods such as RIM molding, rotocasting, and other conventional production techniques. We are very innovative and think entirely in 3D. For example, we internally 3D print our molds for our products and use this in combination with craftsmanship.

Excellent & reliable

Excellence is one of the key pillars of our company. Delivering quality and offering thoughtful solutions ensures that our clients return and refer new ones. We uphold our promises and maintain honesty and reliability throughout the process. Additionally, our innovative approach sets us apart, as we sometimes explore beyond just 3D printing. We offer supplementary services such as assembly, finishing, mold making, and other production methods.

Thinking along in the entire production process.

We go much further than just 3D printing your product. We enhance your entire production process and are only satisfied when you are happy with the end product. In this way, 3D Next Level becomes your strategic production partner. We conduct tests on-site and on our test benches, analyzing your production process together with your technical team: what can be improved, made more efficient, or accelerated? Additionally, we optimize your product for 3D printing to save time, costs, and unnecessary complexity.