Services

Rotocasting

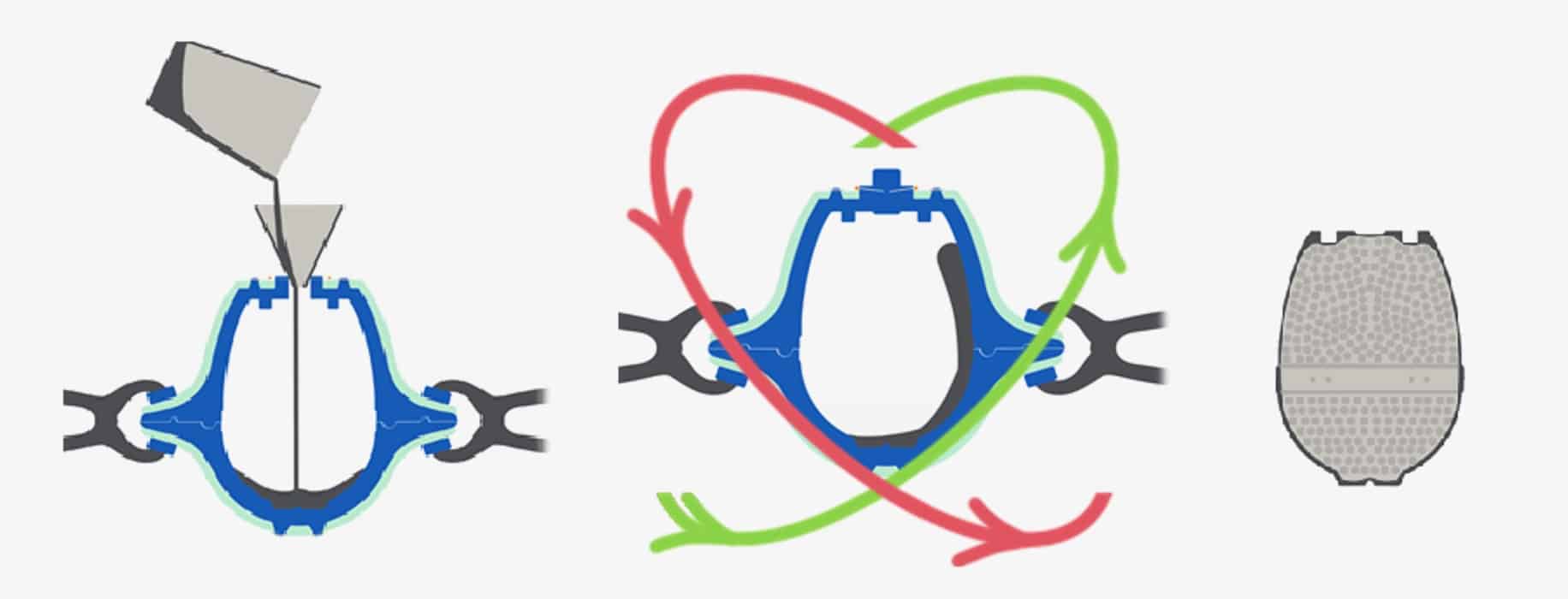

3D Next Level has developed its own rotational molding machine. With rotocasting, we can cast hollow objects intended for small series (reproductions) of 3D objects at a cost-effective price. A first model is 3D printed, then a negative mold is made from it, and in this (production) mold, hollow reproductions can be made using Polyurethane material. This methodology is interesting for quantities ranging from 5 pieces to 500 pieces.

Benefits of Rotocasting:

- Fast production

- Strong and tough Polyurethane materials (thermosets)

- Little to no finishing required; a precise mold also means precisely finished cast products

- Lightweight products

- Costs are low, partly due to minimal labor and low material consumption (hollow)

- Compared to rotomolding (thermoplastics), low startup and mold costs

- Ideal production technique for hollow objects ranging from 5 to 500 pieces

- Complex shapes possible, even with undercuts (combined with silicone molds)

- Various materials available.

Rotocasting is a production method that is not very commonly used in the Netherlands. For this reason, we have built and developed our own machine. Nowadays, we regularly use this technique, for example, when a product needs to be made from a specific material that we cannot offer with 3D printing. Rotocasting is very suitable for casting various materials. We often cast with materials that need to be translucent or extra strong, for instance. The downside of rotocasting is that you need to make a good mold, which is not possible for every 3D object. Rotocasting is an extension for the production of small series of hollow products. It is a cheaper alternative than the well-known rotomolding due to the low mold and startup costs. It is particularly cost-effective for products from 30 cm and up.

The machine

Product example