Services

3D Design & 3D Scanning

"Turn your sketch or idea into a stunning 3D design!"

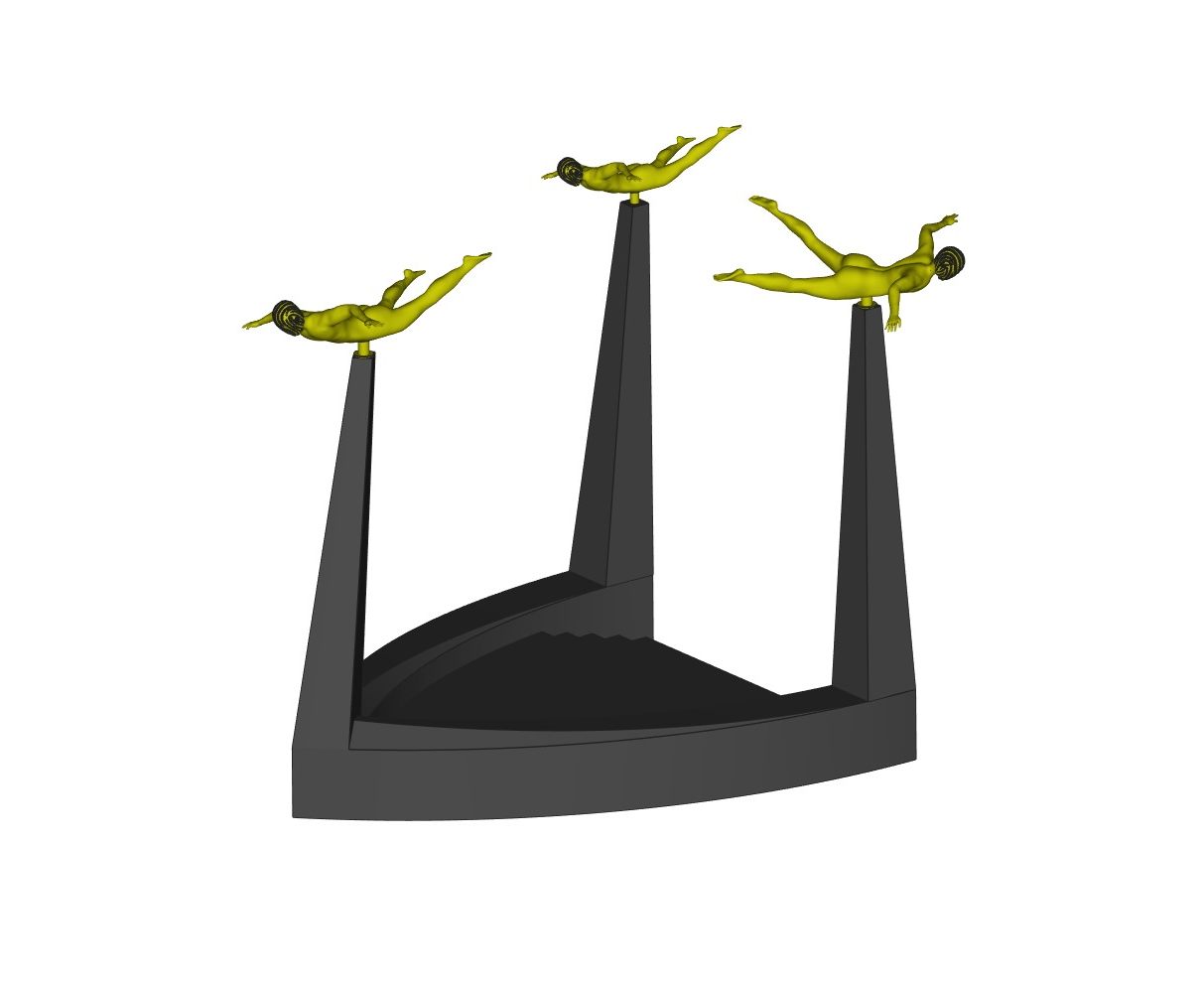

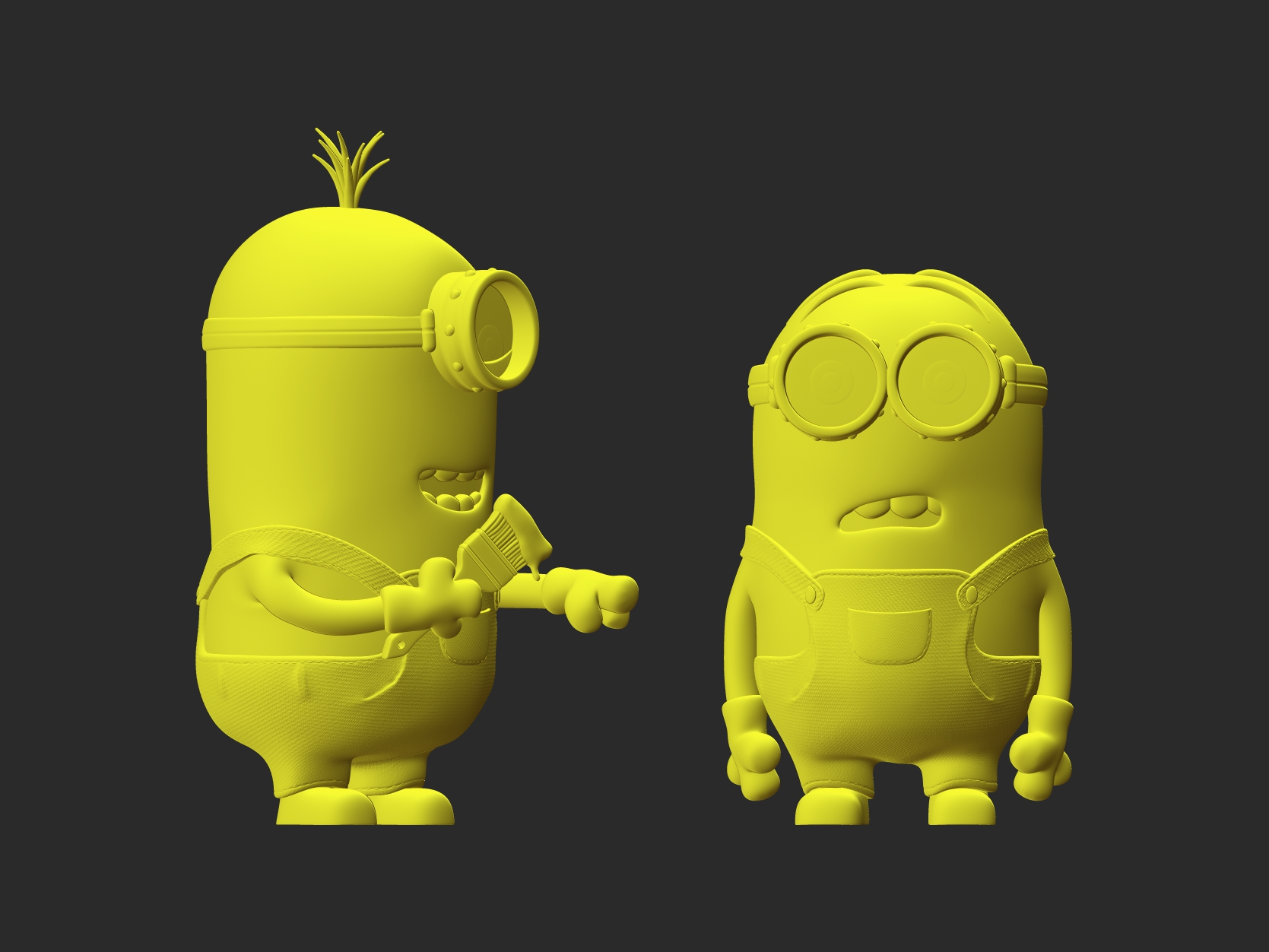

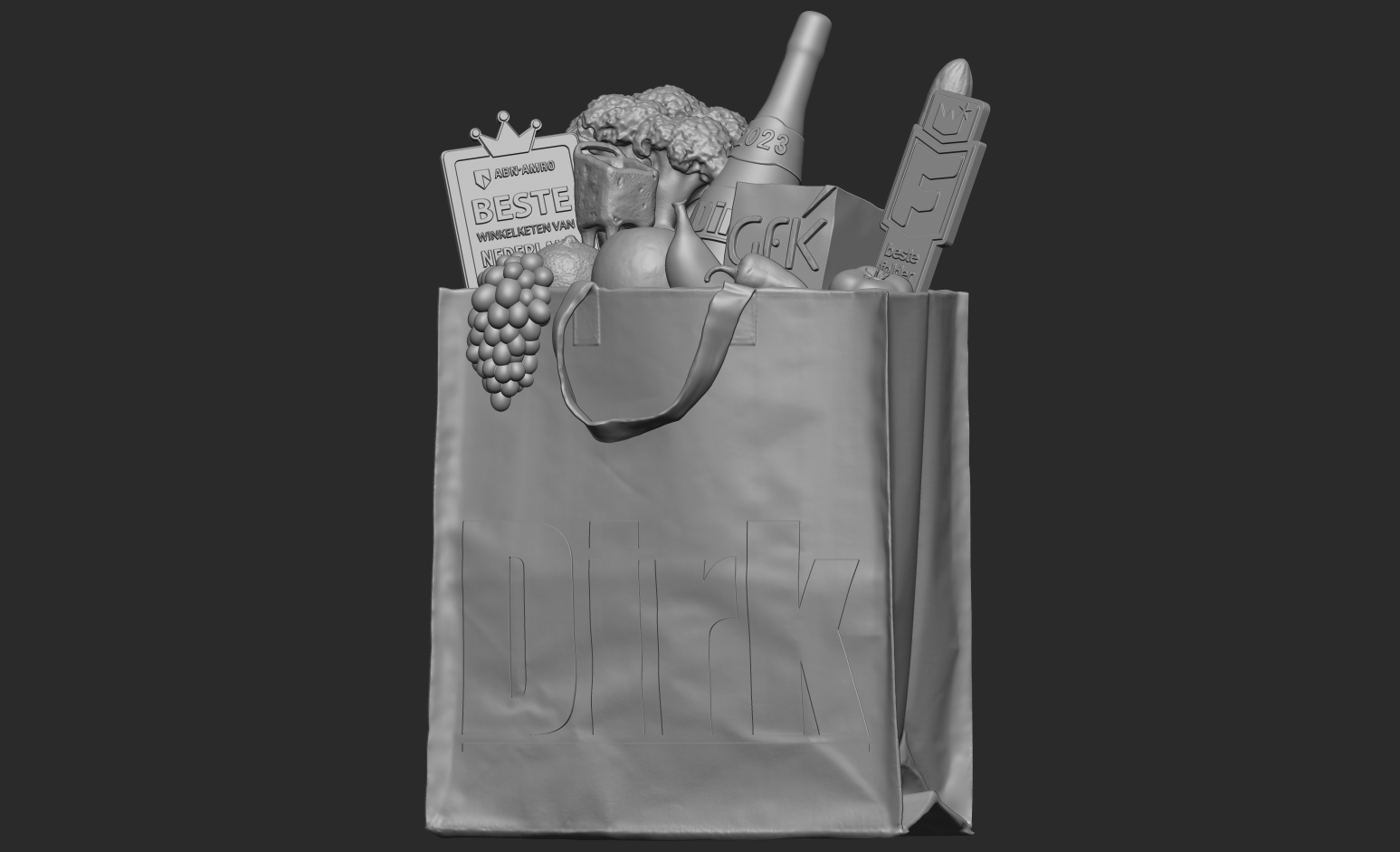

Looking for a promotional object, award, or artwork but don’t have a 3D model yet? We’re here to help you create a professional 3D design. Collaborate with our 3D designer to bring your vision to life!

"We support you from start to finish with your 3D model and project realization!"

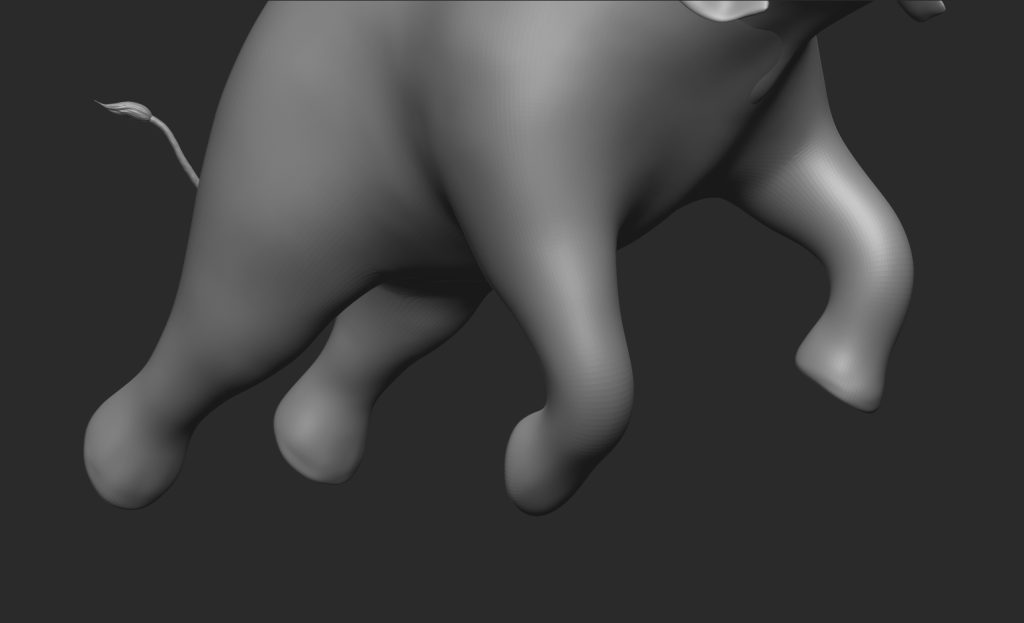

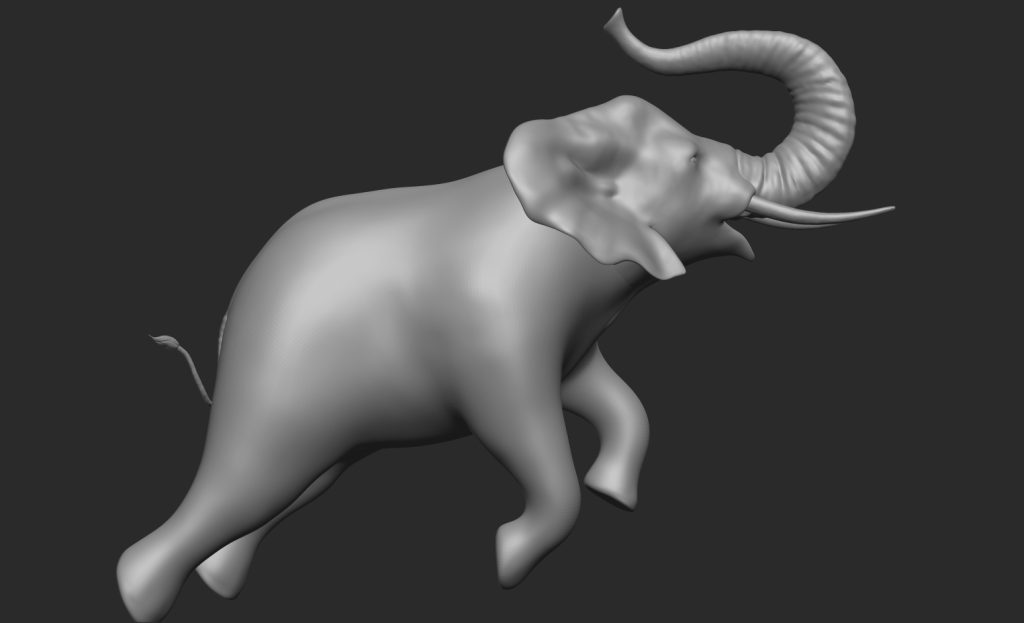

- From quick sketches to highly detailed 3D models

- Revisions and adjustments available

- Designs in Blender, Z-Brush, Photoshop, and Inventor

- Renderings available

- Creative collaboration on your design

- Full project realization after the design phase

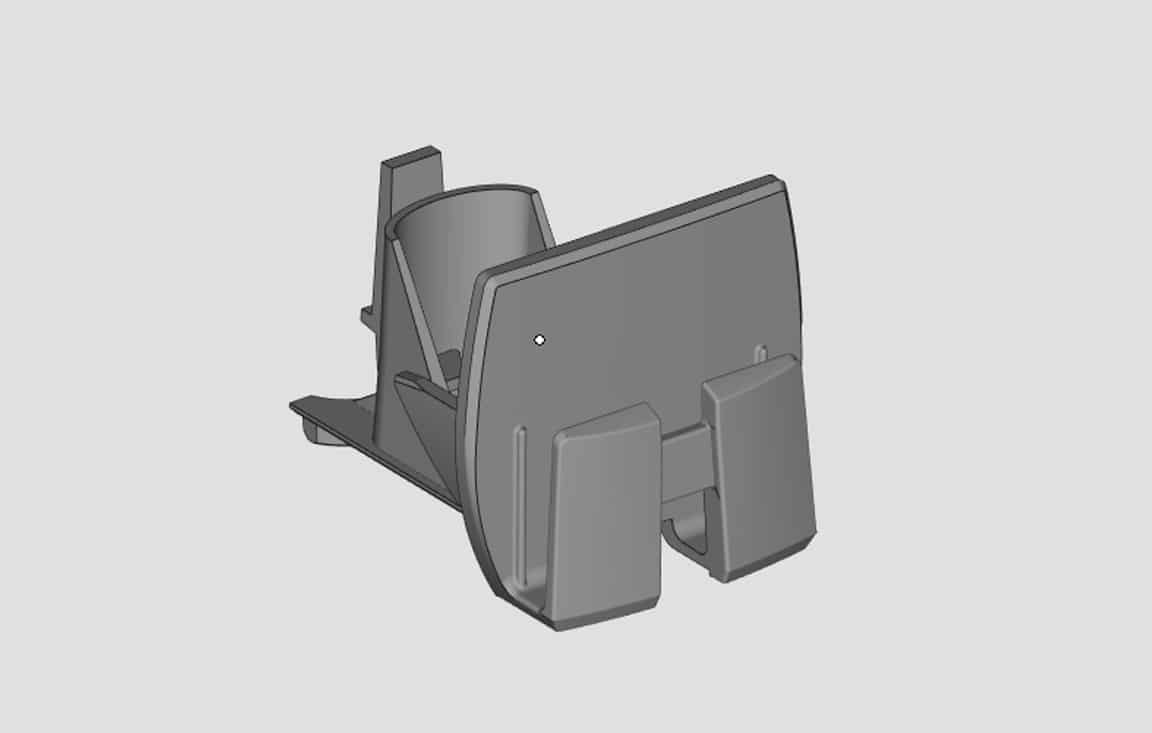

Freeform design

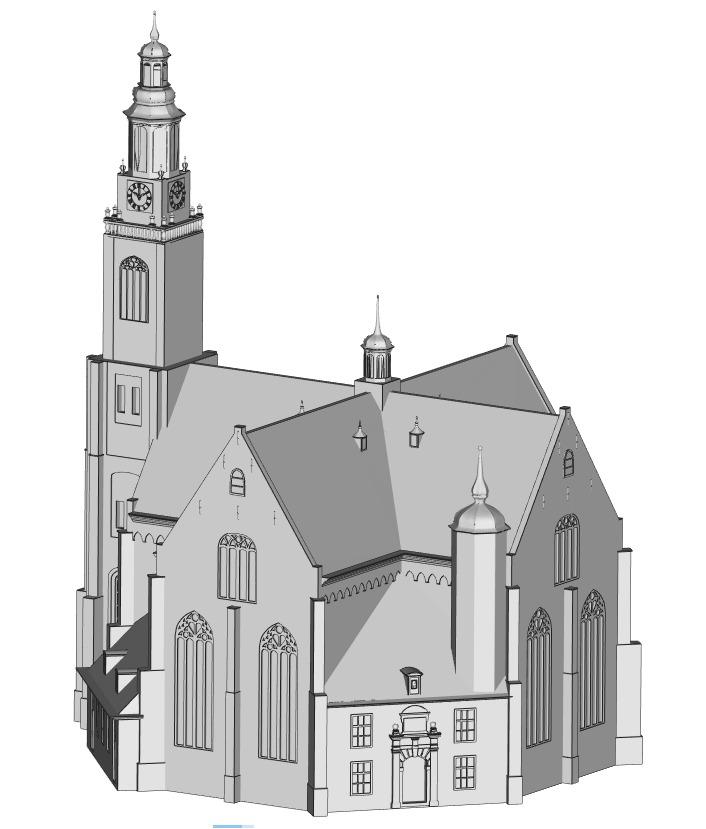

Technical design

What we need from you:

The more specific your input, the better we can craft your 3D design.

- Images or photos as an example

- Detailed sketches with descriptions

- Dimensions and proportions

- Logo files (if applicable)

- Photos of desired textures or structures

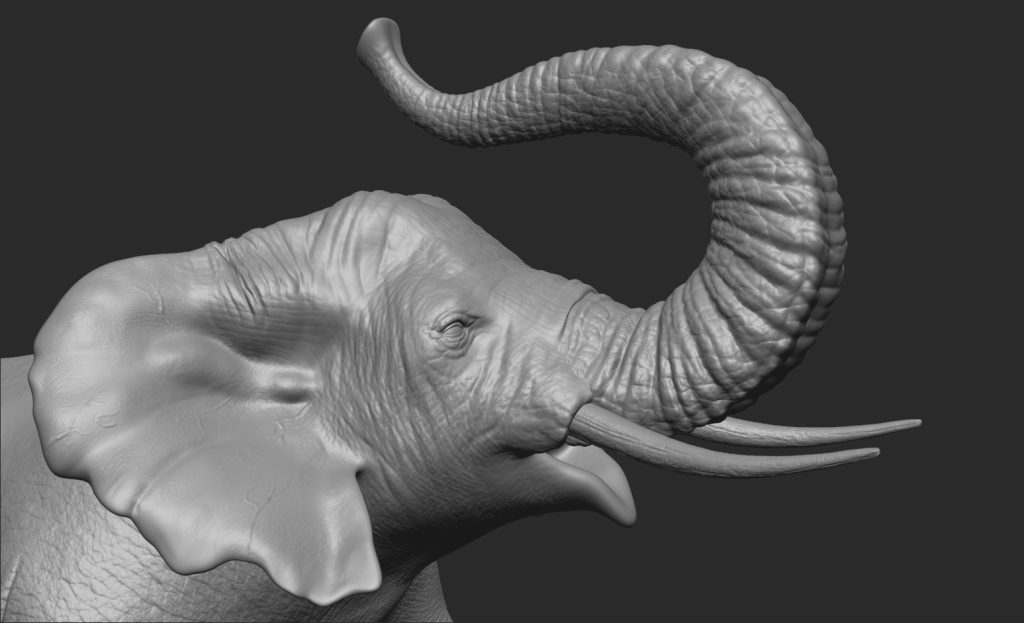

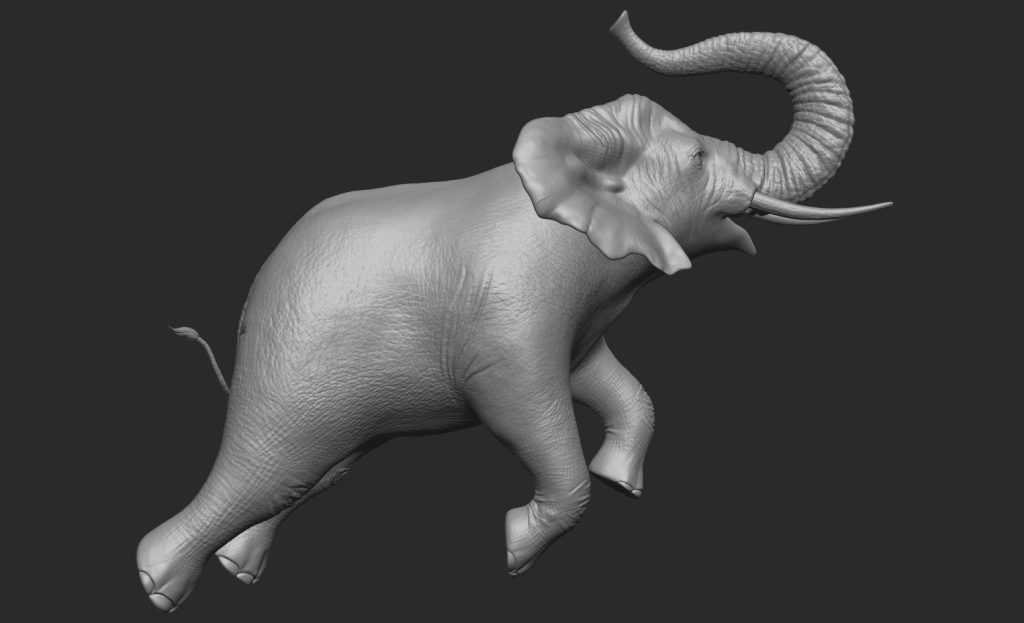

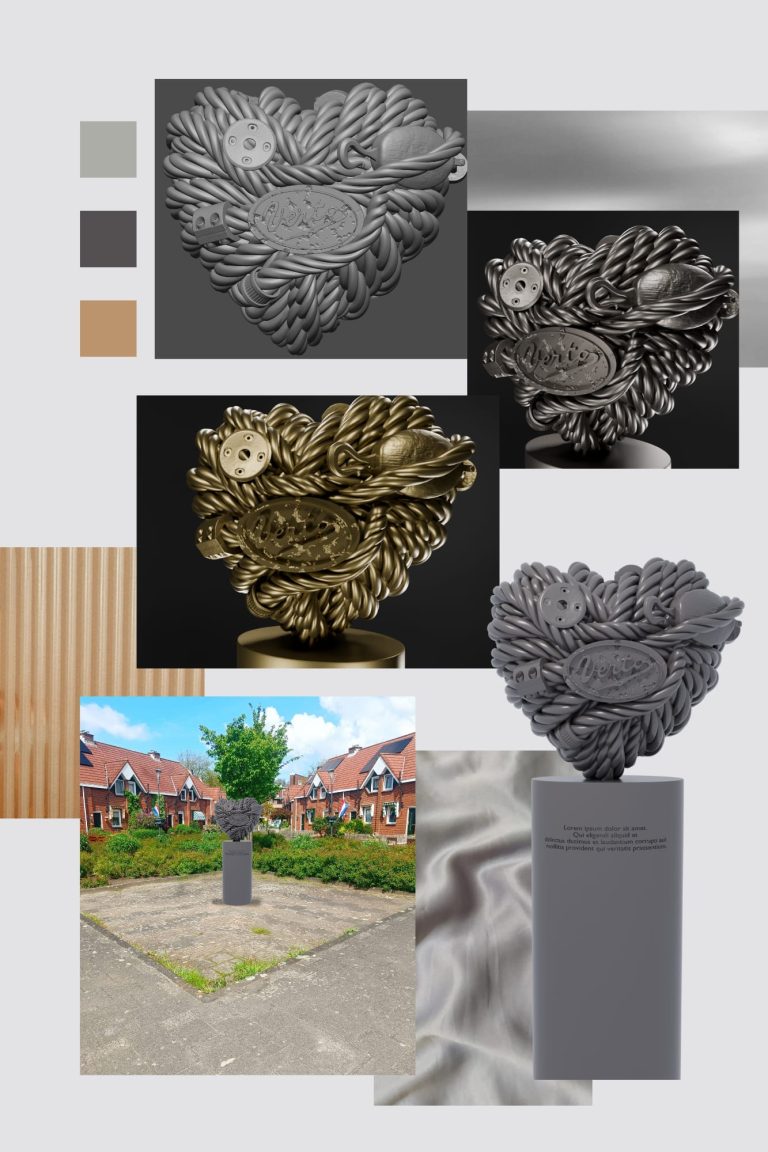

Textures

In addition to smooth 3D models, we can apply textures to your design, such as animal skin or tree bark. Using Z-Brush, we create custom stamp tools to add lifelike textures, making your model truly realistic.

Examples:

- Skin textures

- Surface textures

- Fabric textures

- Wood textures

- Metal textures

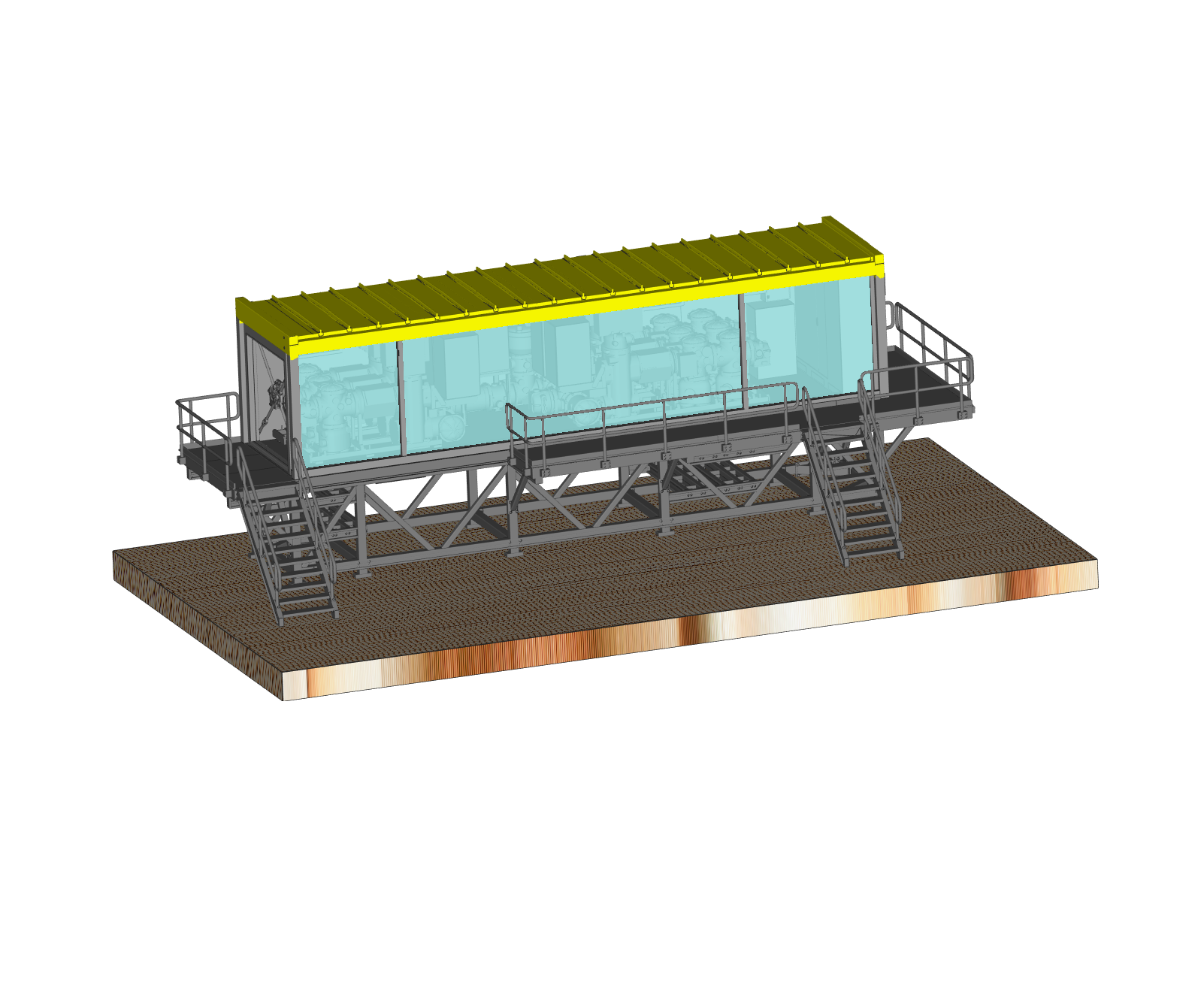

Renderings

After the 3D design phase, we can create realistic renderings of your design. These allow you to showcase lifelike designs for pitching projects, presenting to clients, or applying for grants without investing in full 3D printing and finishing. You can also verify if the design fits its intended environment, color, or finish.

Adjustments are still possible at this stage.

- Realistic visualization

- Cost-saving

- Speed up your project

- Effective communication

- Modern design process

- Wide range of color and specialty finishes

Technical

Art

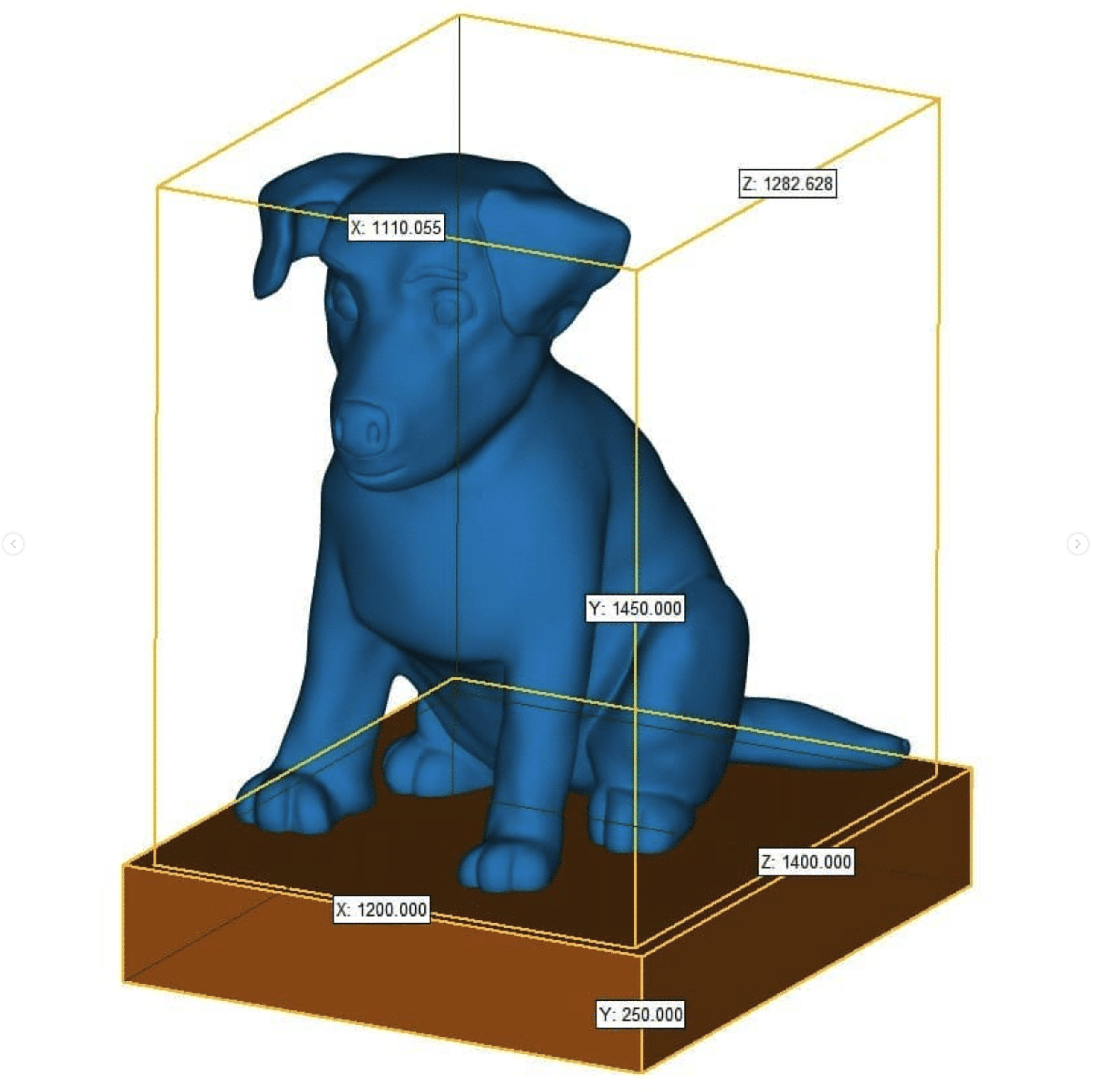

3D scanning

3D scanning is the process of creating a digital 3D model on the computer from an existing physical object. This is done using a scanning device that utilizes light or laser technology to scan an object and convert it into a 3D model. The resulting 3D model can then be further adjusted or edited in our 3D software. For example, the 3D scan can be refined to add more detail to specific areas or even completely modified, and the model can be scaled to the correct dimensions.

- Scaling artworks or objects

- Reproductions and replicas of awards or artworks

- Quality control

- Prototyping, engineering, and product development

- On-site 3D scanning available

Examples of objects we can 3D scan:

- People and body parts

- Existing objects or artworks

- Buildings, structures, and environments

- Cars and other vehicles

- Technical applications