Services

Engineering

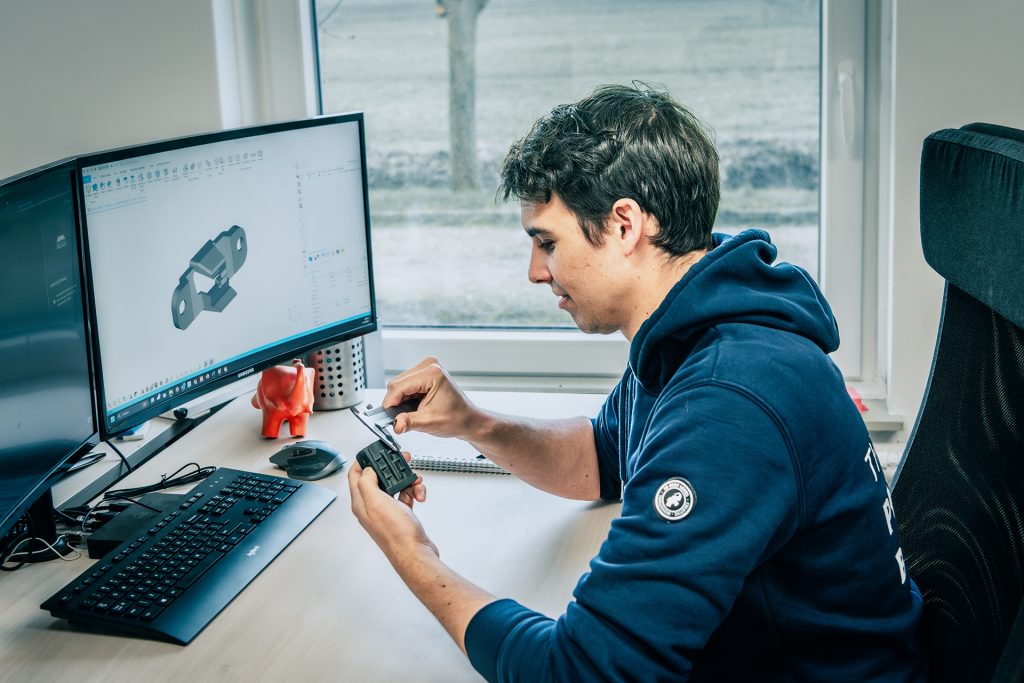

Veel van onze projecten vergen veel denkwerk en engineering. U kunt denken aan een complex of groot kunstwerk met een moeilijke bevestiging. Een reclameobject dat op een auto bevestigd moet worden of een zeer complex schaalmodel van een machine of gebouw. Onze engineers hebben ruime ervaring in het engineren van projecten. Wij staan naast u om dit project tot een succes te maken. Wij leveren high end 3D-prints, maar achter onze projecten zit veel engineering.

Engineering

Bij 3D Next Level hebben we een team van ervaren engineers dat nauw samenwerkt met onze klanten. Ons engineeringproces gaat veel verder dan alleen het uploaden van een 3D-model en 3D-printen. We begrijpen elk detail van wat we printen en denken actief mee met de klant om de beste oplossingen te vinden.

Onze klanten kunnen erop vertrouwen dat we een compleet eindproduct leveren. We bieden ook diverse aanvullende productiemethodes in huis aan, zoals rotocasting, rim-molding en aflakken, om aan verschillende eisen te kunnen voldoen.

Wij testen ook onze 3D-objecten of alles klopt en werkt. Zodat u of wij tijdens de installatie niet voor verassingen komen te staan. Op het oog lijkt een 3D-object vrij eenvoudig, maar er zit bij 3D Next Level een slim stuk engineering achter. Wij denken vooraf alles uit, engineren alles vooraf in ons 3D-model en gaan dan pas verder met 3D-printen en het maken van het eindproduct.

We believe in providing comprehensive service and take responsibility throughout the entire process. From the initial contact to the delivery of the final product, we offer a complete journey from A to Z. Our customers can rely on us for expert guidance, innovative solutions, and high-quality products.

Request a quote

Slimme engineering